| Nano-D Series |

|

|

| Nano-D Zinc Oxide (ZnO) dispersion |

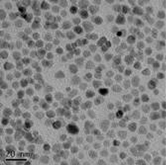

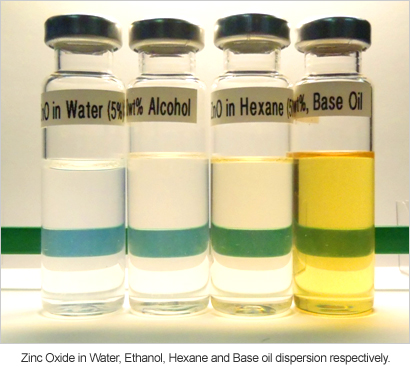

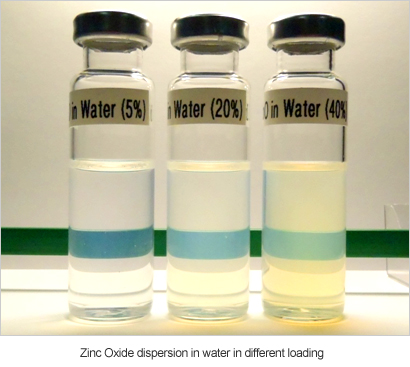

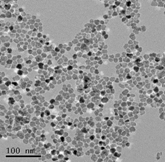

Zinc Oxide is a white inorganic compound which is not readily dissolved in both water and solvents. With HGCP technology, Nano-D Zinc Oxide (ZnO) nano-particles can be dispersed in water and various solvents to achieve a highly transparent, stable and very high solid loading (50% or above) mono-dispersion.

|

| TEM of Nano-D ZnO nano-particles |

|

|

|

Nano-D ZnO dispersions are now available in various commonly used organic solvents such as toluene, ethanol, MEK, butyl acetate, ethyl acetate, and it is also available in aqueous form. Loading ranges from 30% to 50% depending on media selection. The product is also available for certain dispersing system in crystal powder form for easy and cost effective transportation.

|

Product Code |

Nano-particles |

Non-volatile matter (wt%) |

Dispersing Medium |

Typical Particle Size, D50 (nm) |

Nano-D 133P |

Zinc Oxide |

30 ~ 50 |

Non-polar |

Toluene, Hexane, Petroleum Ether, etc

(in dispersion or crystal form) |

25 |

Zinc Oxide |

30 ~ 50 |

Base Oil

(in concentrate form) |

40 |

Nano-D 133D

|

Zinc Oxide |

30 ~ 50 |

Polar |

Methyl Ethyl Ketone (MEK), Acetone, etc

(in dispersion or crystal form) |

37 |

Zinc Oxide |

30 ~ 50 |

Ethanol, etc

(in dispersion or crystal form) |

18 |

Zinc Oxide |

30 ~ 50 |

Butyl Acetate, Ethyl Acetate, etc

(in dispersion or crystal form) |

25 |

Zinc Oxide |

30 ~ 50 |

Dipropylene Glycol Methyl Acetate (DPMA)

(in dispersion or crystal form) |

10 |

Zinc Oxide |

30 ~ 50 |

1-Methoxy 2-Propanol (in dispersion or crystal form) |

14 |

Nano-D 133W |

Zinc Oxide |

30 ~ 50 |

Water

(in dispersion form) |

20 |

|

|

|

Nano-D ZnO delivers a highly stable, long-term, non-leaching and broad spectrum UV protection more cost effectively compared to other nano-particles and conventional organic UV absorbers. Nano-D ZnO has been used in various applications which exposed to highly destructive UV radiation in harsh environments such as wood and furniture protection coatings, plastics, silicones, engineered polymers, cosmetic etc. Nano-D ZnO has many functional properties similar to that of Titanium Oxide (TiO 2), hence, it is able to substitute TiO 2 in many applications.

Nano-D ZnO dispersion is suitable for solar control coatings or films especially in the architectural buildings and automotive industry when incorporated together with Nano-D Antimony Tin Oxide (ATO) dispersion. The incorporation of Nano-D ATO and ZnO in coatings or films facilitates the screening off of heat radiations from IR and UV rays respectively, yet allowing most of the visible light to pass through. This ability is due to the very high transparency of fully dispersed nano-sized ZnO and ATO particles which do not impeded the transmission of most of the visible light spectrum.

Nano-D ZnO nano-particles can be incorporated into base oil as Nano-D ZnO Concentrate - a ready-use performance booster for lubricants such as grease, motor oil, gear oil, etc. It acts as anti-oxidation agent in the lubricants to prolong the usage life, by destroying the free radical chain reaction and reduces the presence of metal ions which accelerate the oxidation of the hydrocarbon chains in the lubricants. These free radicals if not captured will speed up the oxidation of the hydrocarbon chains in the lubricants resulted diminishing performance and not usable.

If you are interested to know about Nano-D ZnO dispersions, please contact us for a discussion to assists you to identify the ideal Nano-D ZnO dispersions suitable for your applications. Alternatively, you can reference to our Product Information Centre for more Product Information and MSDS. |

| BACK TO TOP |

| |

|

|

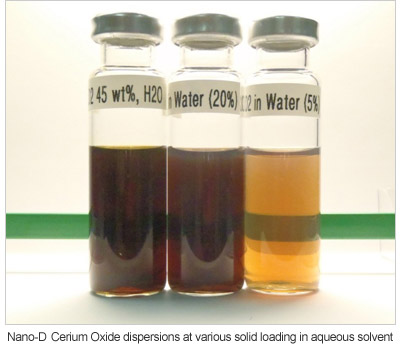

| Nano-D Cerium Oxide (CeO2) dispersion |

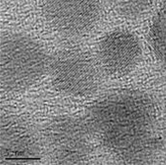

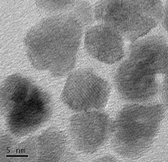

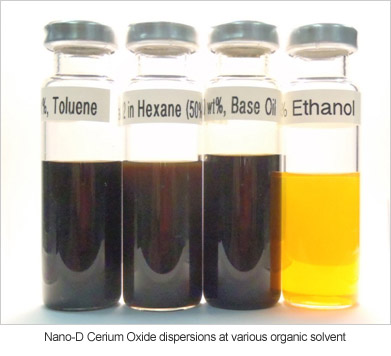

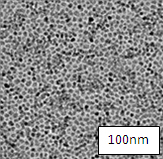

Nano-D Cerium Oxide nano-particles is a product derived from patented HGCP Technology coupled with proprietary dispersion technology. Nano-D Cerium Oxide nano-particles have minimal agglomeration with very narrow particle size distribution. Nano-D Cerium Oxide dispersion is highly transparent even at very high concentration (up to 50 wt%). |

| TEM of Nano-D Cerium Oxide nano-particles |

|

|

|

Nano-D Cerium Oxide nano-particles are available in dispersion, concentrate or crystal powder form. The solid loading ranges from 30% to 50% depending on media selection. The dispersion/concentrate form can be used directly into the formulation of the product. |

| Product Code |

Nano-particles |

Non-volatile matter (wt%) |

Dispersing Medium |

Typical Particle Size, D50 (nm) |

| Nano-D CEP |

Cerium Oxide |

30 ~ 50 |

Polar |

Ethanol, 1-Methoxy 2-Propanol, etc.

(in crystal form) |

24 |

| Nano-D CEN |

Cerium Oxide |

30 ~ 50 |

Non-polar |

Base oil

(in concentrate form) |

33 |

Cerium Oxide |

30 ~ 50 |

Diesel, Hexane and Hydrocarbon solvents

(in dispersion form)

|

48 |

| Cerium Oxide |

30 ~ 50 |

Toluene (in dispersion form) |

39 |

Nano-D CEW |

Cerium Oxide |

30 ~ 50 |

Water (with surfactant), pH > 8

(in dispersion form) |

58 |

|

|

|

Nano-D Cerium Oxide nano-particles absorb UV light in the light wavelength region between 300nm to 400nm, are incorporated into applications such as wood and furniture protection coatings, plastics, silicones, engineered polymers, cosmetic etc., similar to that of TiO 2 applications. Nano-D CeO2 nano-particles has uniquely ultra-low photo catalytic activity making it more suitable than TiO 2 for long lasting protection on coatings application such as wood coating and glass coating without deteriorating the binder in the coating. In wood-coating, it gives a natural light amber color to the wood and furniture.

Nano-D Cerium Oxide dispersion can be incorporated into base oil as Nano-D Cerium Oxide Concentrate, working as a performance booster and as anti-wear agent at extreme pressure for lubricants such as grease, motor oil, gear oil, etc., by preventing premature deterioration due to prolong friction.

Nano-D Cerium Oxide nano-particles act as fuel-borne catalyst when dispersed in fuel oils such as diesel fuel, where it can improves the combustion of the diesel fuel to give cleaner emission and better protection to the metallic parts of the engine, mainly due to the high accessible surface area of Nano-D Cerium Oxide nano-particles and its oxygen storage capability.

If you are interested to know about Nano-D Cerium Oxide dispersions, please contact us for a discussion to assists you to identify the ideal Nano-D Cerium Oxide dispersions suitable for your applications. Alternatively, you can reference to our Product Information Centre for more Product Information and MSDS. |

| BACK TO TOP |

| |

|

|

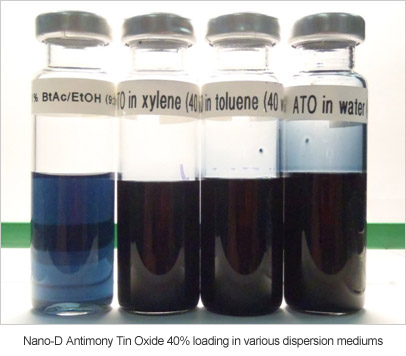

| Nano-D Antimony Tin Oxide (ATO) dispersion |

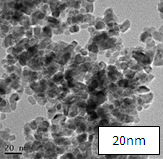

Nano-D Antimony Tin Oxide (ATO) nano-particles are derived from our patented HGCP Technology coupled with proprietary dispersion technology. ATO dispersion is highly transparent with high solid content of up to 40wt%. Nano-D ATO nano-particles have minimal agglomeration with very narrow particle size distribution. The mean particle size in the dispersion is below 100nm (using Dynamic Light Scattering). |

| TEM of Nano-D ATO nano-particles |

|

|

|

Nano-D ATO nano-particles are available in dispersion, concentrate or crystal powder form. Solid loading ranges from 30% to 50% depending on media selection. The dispersion/concentrate form can be used directly into the formulation of the product. |

| Product Code |

Nano-particles |

Non-volatile matter (wt%) |

Dispersing Medium |

Typical Particle Size, D50 (nm) |

| Nano-D ATN |

Antimony Tin Oxide |

30 |

Non-polar solvent such as Toluene, etc. |

103 |

Nano-D ATP |

Antimony Tin Oxide |

30 |

Polar solvent such as Ethanol, Butyl Acetate , etc. |

40 |

| Nano-D ATW |

Antimony Tin Oxide |

40 |

Water |

34 |

|

|

Nano-D ATO dispersion can be integrated into surface coatings to effectively shield the radiant heat without significant effect on the optical or other physical properties of the applied surface. Nano-D ATO is a potential low cost substitute for indium tin oxide (ITO) coatings for solar or display application.

Nano-D ATO nano-particles shield energy in the near infrared region and at longer infrared wavelengths, while maintaining excellent transparency in the visible region. Attenuating infrared energy from the sun or other sources allows cooler temperatures to be maintained during summer and control of heat loss during winter, which is energy-saving through reduced air-conditioning.

Nano-D ATO nano-particles can be integrated into surface coatings or polymer composites to provide anti-static and static dissipative properties, which can be used in sensitive environments such as electronic packaging and assembly and provide protection from destructive electrical discharges that can harm the components.

If you are interested to know about Nano-D ATO dispersions, please contact us for a discussion to assists you to identify the ideal Nano-D ATO dispersions suitable for your applications. Alternatively, you can reference to our

Product Information Centre for more Product Information and MSDS. |

| BACK TO TOP |